| Home | Material | My Telescopes | Mirror Making | Deep Sky | ext. Links |

| 32" Mirror | 24" Kyklopas | 17,5" Aristarchos | 14" Mirror | 10" Archimedes | 10" Travel Dobson | 24 cm Quints | 17 cm Twins | 6" Traveldobson |

| Deutsch (de)![]()

| Home | Material | My Telescopes | Mirror Making | Deep Sky | ext. Links |

| 32" Mirror | 24" Kyklopas | 17,5" Aristarchos | 14" Mirror | 10" Archimedes | 10" Travel Dobson | 24 cm Quints | 17 cm Twins | 6" Traveldobson |

14" f/4.5 Ultrathin Mirror

The essential step to an ultralight Dobson that cools down quickly is a thin mirror. But how thin can it be? I tried it with a 360 mm (14") Schott borosilicate blank of 20.6 mm (0.81") edge thickness (at f/4.5 the center is 15.6 mm (0.61") thick). The blank showed no internal stress in the cross polarizer test with a LCD display of a notebook. It is not really advisable, to work with so thin a "Pizza", the additional problems with flexing are not trivial. But I wanted to see how far I can push the limits. If you have no experience in mirror making, I recommend, not to go so thin.

Hogging out I did with a grinder similar as Kurt

Schreckling and others in To flex or not to flex .. have shown, but I used instead of a diamond disk a normal grinding tool for stone (see picture). Don't take those for Steel, they don't work for glass. The blank was put into a tub with water, so that the water level was slightly above the surface. Put on your safety goggles, dust mask, gloves and ear plugs and wwwwwinnnng ![]() . It splashed around a bit, but no dust in the air! I swung the machine free hand back and forth without using a fixture or a router. I just rotated the blank from time to time and measured the depth at different points. A 1 cm wide edge was left unground, to prevent edge chipping. If you don't like the freehand method, see the wood jig + blank rotator a lá Robert Nowak, or the radius generating machine of Wolfgang.

. It splashed around a bit, but no dust in the air! I swung the machine free hand back and forth without using a fixture or a router. I just rotated the blank from time to time and measured the depth at different points. A 1 cm wide edge was left unground, to prevent edge chipping. If you don't like the freehand method, see the wood jig + blank rotator a lá Robert Nowak, or the radius generating machine of Wolfgang.

Later attepts showed, that it is not nessessary to cool the glass with water, you can dry grind a well. But this produces a lot of dust, so work outside only and with tailwind. Take all the care, not to inhale the dust, a well sealing dust mask is a must!

Warning: Working with the grinder can be dangerous, as particles can fly around at high speed! Therefore protective clothing is absolutely necessary. The RPM shall in no case be higher than the grinding tool is specified for, otherwise the tool can be degenerated due to the high radial forces. My grinder has a speed control and I use it at safer 3-6,000 RPM.

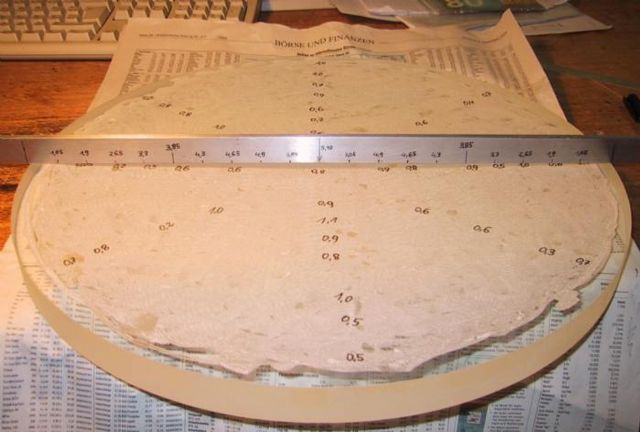

I controlled the sagitta at several spots, to see, where to remove how much glass. On this picture there is shown a 16" f/5 with 25 mm edge thickness, the numbers on the blank are mm thickness that are still to be removed.

The surface looked like that of a canyon land, so I smoothed it out with a 10" Duran glass Tool and carbo #80 and brought it to the final depth.

From 4,75 kg (10,45 lb) at the beginning there was 4.0 kg (8.8 lb) left at a sagitta of 5 mm. Hard to believe, that such a thin blank will work.

The rest of the glass was spread all over the balcony - a big mess. Working by hand with carbo #60 would have taken me 14-16 hours of full power grinding.

The fine grinding I did with the same 10" glass tool working tool on top. The steps was grit 180, 320, 600, Alox 9m, Alox 5m. At the finest stage the thin mirror flexed under a too high pressure and the tool dug scratches into the glass. I had to go back to grit 320 and apply later a more gentle or no additional pressure at all.

The back side of the mirror was ground flat against another glass with grit #180 and smoothed with #320. Also I took care, to remove any residual wedge in the glass (same edge thickness all over). I believe, that this is essential, to prevent uneven bending during polishing, which would result in astigmatism.

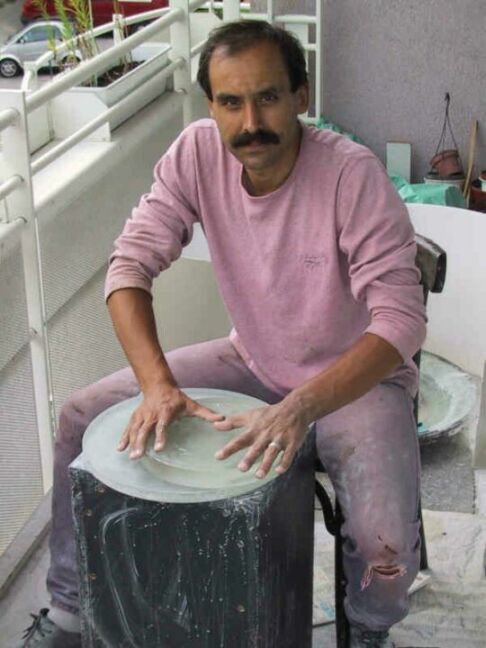

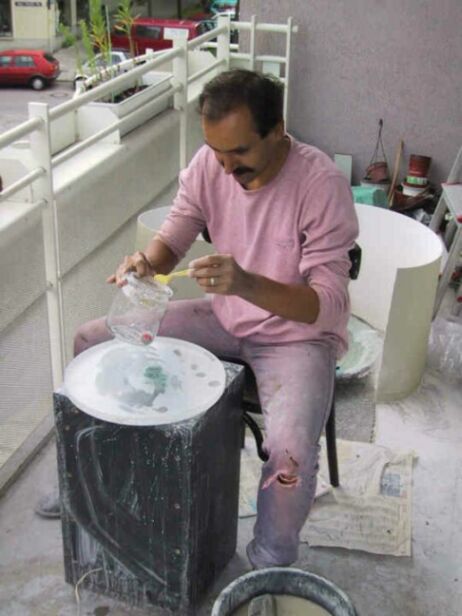

For polishing I used a 5 kg (11 lb) 12" plaster tool with 28° pitch from Piering and the fine Ceroxyd suspension CERI 3000 from Pieplow & Brandt. I polished TOT on a piece of carpet on a flat underground (see picture) on which the mirror was frequently rotated. The use of a turning table, which I sometimes see, does not help here, it's essential to rotate the mirror itself! Otherwise all unevenness on the underground will press always against the same spot of the mirror an will print trough. After 8 hours rapid polishing the mirror was polished out, but showed a central hill, which I could not explain. Was it due to flexing under the heavy tool? I put a 0.3 mm (1/80") thick carton UNDER the central part of the carpet as a support and after half an hour the mirror was exactly spherical. This reminds me of the fairy-tale with the princess and the pea under her mattress. This is no joke, so sensitive can glass react.

The main part of the parabolizing I did TOT with a 6" star tool applying W- and tangential strokes and finished with the large tool, to get a smooth surface. It took me some time, until I understood the flexing effects during figuring and measuring. Like at the polishing stage the same rules apply here: Work on a flat and stable table and use a soft and homogeneous underground like a rubber mate or carpet under the mirror (see picture) and to rotate the mirror frequently. In addition to this, I change the stroke direction continuously (back and forth, left - right, X-ing diagonal), to prevent asymmetrical wear. (see also at the 32" polishing for more details). It's highly recommended, to star test thin mirrors on astigmatism, as you can't be really sure, that everything will be symmetrical automatically.

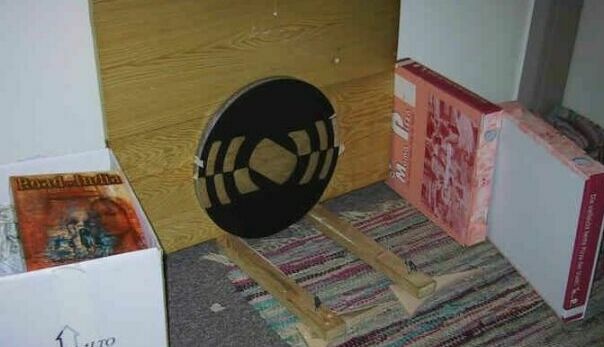

For testing I placed the mirror plainly onto two wood bars (see picture with the Couder mask). On the absolutely spherical mirror (and only there) in the Foucault there was visible the deformation due to the mirrors own weight as small shadows, which extended 2-3 cm (1") into the inner surface. I addition to this, the flipping over of the mirror (potato chip effect) could be seen as a weak Ying Yang shadow pattern. Finally, I decided to ignore this effects, since I tested just the neutral horizontal zone anyhow and this is deformed homogenously and the zone readings (and thus the overall correction) should remain unchanged. This was at least my "highly sophisticated theory", that I put together. Isn't it fine, that you can build theories together as you like them, if you have no other choice ![]() ?

?

At the end, my thin "Pizza plate" had to give by and the parabola was polished into the glass (see Foucault Image). With the 6 zone Couder mask I measured following Foucault test results (60 KB Excel sheet or 20KB .gif image ). Even if the truth is a bit away from that, the star test with a friend's scope looked very promising and most important for me - no hint of astigmatism was visible.

4 kilograms for a 14 inch optics - that's the way I like it. Having finished the mirror, it will take some time before I will start to build the scope, but there are some "ultralight ideas" in my head already. I am dreaming of how it feels, to expose the Eta Carina Nebula from the Australian Outback with 14 inches power onto the retina.

Update: The build of the mechanics never materialized, there are existing only draft sketches. But I had made 2 of theese mirrors and the second Jörg build into a nice ultralight traveldobson.

To top of this page

Home | Imprint | Privacy Policy | about |